After the three primary human essentials (food, water, and shelter), you can add clothing to the top section of this list. In its simplistic sense, this makes the textile industry very vital to us all. Nigeria’s textile industry significantly contributes to its economy through its role in the manufacturing sector. Amongst all other manufacturing sectors in Nigeria, the textiles and garments industry is the largest.

Let us take a close look at this industry and how you can start to own equity. Nigerians must think of owning equity in the industries that hold the nation, as this keeps the authority and ownership for the people. A primary way to own equity is to develop strong businesses within these industries. To achieve this, you must understand the sector, its value and the potential future of equity.

Contribution to the Economy

The textile industry is more than clothing. Added to traditional clothing, you have interior deco, footwear, leather, and other sub-sectors. Textiles, apparel, and footwear are the second-largest output activity. To learn more about the technical aspects of fabric and textiles, read our blog “Beginners Guide To Fabric”. The leather and leather product sub-sector exports are estimated to be about $272 million, with a high potential to generate over $1 billion by 2025. In addition, the industry employs approximately 750,000 people, including around 500,000 in the finished leather goods business, mainly women, who make up the bulk of the workforce.

The Nigerian textile industry was the second largest in Africa behind Egypt before 1997, with over 250 active plants and over 50% capacity utilisation (Semshak Gompil 2004).

The history of textile that we know nothing about.

Our generation barely remembers the great cloth industry today’s regions that form Nigeria had around the 15th century. Such historical information was not taught in our history classes. The Nigerian textile industry used to be the second largest employer of labour after the government, employing over one million Nigerians and generating over N1 billion in revenue for the Nigerian government. It was also a significant user of locally produced raw materials such as cotton and polyester. But now, Nigeria has 25 textile mills, with an average capacity of 40% and a total workforce of roughly 25,000 workers.

Does Nigeria still process and produce textiles?

Let us not believe that Nigeria produces most of its textiles. Even when some are processed and made within the country, the bulk is imported. The primary workforce in this industry does not come from the direct processing of raw materials or the manufacturing of fabrics. Instead, the workforce revolves around the production of fashion, footwear and other finished product, which primarily rely on importing processed raw materials or semi-finished materials such as fabrics. Also, the production of these finished goods is limited. The quantity and quality often do not meet (and in some cases, appeal to the taste) the growing population’s demand.

Impact of not processing raw materials for the textile industry

Since more workforce relies on imported materials to further prepare a finished good, Nigeria’s needed entrepreneurial spirit of innovation is not cultivated. Resources, education and investment capital are not directed towards this sector’s deliberate development. This attitude makes the needed machinery unavailable in Nigeria. Hence the skills required to operate and repair such machines are limited or, better said, not present. Any form of development one pursues needs a strategy. Read “Development In Africa Needs A Europe Strategy”. For investment into the textile industry to be significant, significant enough for a bulk of the Nigerian people to own equity, we suggest that these 5 areas have to be properly looked into as an entrepreneur;

- Developing new sustainable raw materials for textile production.

- Developing machinery training and repair procedures.

- Designing production facilities that are Autakt.

- Re-innovating machinery for this purpose.

- Harnessing research and development capital for invention.

Who do we need on board now?

This process is a very capital and time intensive one. More prominent investors have to be on board for this approach to be favoured. Investors can be the federal or state government. However, this can be achieved on a much smaller scale if a strategy exists. A group of medium-sized textile entrepreneurs team up to form cooperation with a clear goal. Or, if you choose a lonely road to start, then engage with a “signature product” approach.

Use a B2B “signature product” approach if you go solo.

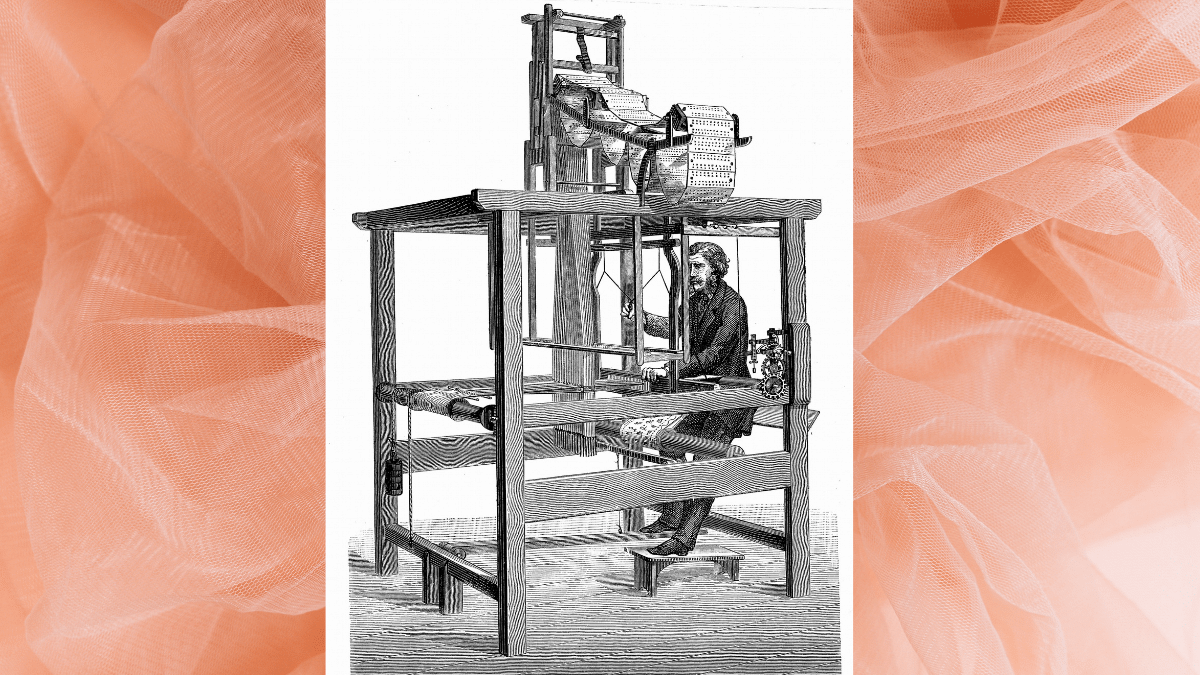

A small-Medium entrepreneur can research one of two primary products made at least 80% in the country, maybe like Aso-oke. Partner with the yarn producers to find better and consistent quality. For example, you can get softer yarns from the mills or import them if possible. Take a look at the Aso-oke weaver’s loom. It can be supported with more mechanics and maybe upgraded with electronics.

I know there is already automated machinery for this. But remember that if you employ highly sophisticated technology with no knowledge to use and maintain it, you will not succeed. So a transitional approach can work. A path where you start from the manual and move towards a sophisticated one. By doing this, you and your network can begin to gather the know-how for the machinery and maybe launch a branch for the production of the machinery, its parts, and repair.

Textile Machinery and engineers

Approach companies that produce electrical looms for partnership. You are good to go with two manual looms, one semi-manual, and one electrical loom. Rember that there are talents on the ground who can convert a fully manual loom to a semi-automatic loom. Utilise this talent. Look for this talent. These people should become your machine engineers.

Master your lane, export with confidence

Source for yarns and begin to design fabrics. Your focus is to master and develop robust expertise in fabric making. Your customers are designers and those making the finished designs. This same approach can go for other kinds of fabric designs like Adire. However, the more you specify and focus on detailed aspects of the supply,y chain, the better you become. You become innovative and find top-level partners ready to collaborate. This allows you to grow faster. Suppose you worry that you might not have enough clients; look at the European market. Maybe you want to think of exporting. But to be able to partake in a market with high fabric technology, make sure all these things apply to your product to boost competitiveness:

- It is eco-friendly (with proof).

- It has a strong social impact (Measurable).

- The durability is outstanding. (tested and proven).

- There is a uniqueness about it – design, texture, story etc.

When you spread yourself too thin to produce fabric and make fashion, you will face challenges that arise from repeating problems, and you will become stagnant.

Make it a collaborative journey for it to be worth the while

Using this method, you can find people specifying in a participle area. It could be someone who specialises in making buttons from plastic or wood. Someone who specialises in the mass production of garments. Someone else could focus on making the best shoe soles. Using these tactics, you can develop a strong network within the industry and begin to lobby for your legislation, seek global partnerships and showcase in international fairs. On JoadreTribe App, we will explore a more in-depth strategy to start and grow your manufacturing empire.

We are following up on what the government is doing.

The government has mandated that the military, paramilitary agencies, and government institutions acquire made-in-Nigeria textiles and apparel solely for their uniforms. At the same time, the private sector, particularly schools, should be encouraged to source materials locally. The policy would ensure that adequate standards are developed in the sector and that all significant textile importers are registered with the Standards Organisation of Nigeria (SON) to reduce the dumping of substandard goods in Nigeria, and a bilateral agreement between SON and its counterpart in China to significantly reduce counterfeiting.

Do you think the government is doing enough? Let us know what your take is on this by sending us an email to [email protected].

Get our app, stay in touch, and let us help you develop your Ideas.

We created our tailored all-in-one app to offer up-to-date knowledge, provide exposure for social entrepreneurs and offer coaching services. Get the app (Android version) here. For IOS users, a web app and IOS version are on their way; sign up for our newsletter here to know when it is out and get consistent resources via email. If you need templates to develop your ideas, you can check our Joadre Tools. If you want to contact us, use our contact form or consult us through the app.

Thank you for reading to the end.

Cheers

Joadre